Table of Contents

Report

CoffeeMush

Acknowledgement

Glossary

Table 1 contains all abbreviations and their meanings.

| Abbreviation | Description |

|---|---|

| ABS | Acrylonitrile Butadiene Styrene |

| AC | Alternating Current |

| AI | Artificial Intelligence |

| API | Application Programming Interface |

| CAD | Computer-Aided Design |

| CE | Conformité Européenne (European Conformity) |

| CEO | Chief Executive Officer |

| DB | DataBase |

| DC | Direct Current |

| dB | Decibel |

| EC | European Commission |

| EPS | European Project Semester |

| EU | European Union |

| GB | Gigabyte |

| GPIO | General Purpose Input/Output |

| HEPA | High Efficiency Particulate Air |

| HTTP | Hypertext Transfer Protocol |

| HTTPS | Hypertext Transfer Protocol Secure |

| I2C | Inter-Integrated Circuit |

| IO | Input/Output |

| IP | Internet Protocol |

| ISEP | Instituto Superior de Engenharia do Porto |

| ISO | International Organization for Standardization |

| KB | Kilobyte |

| LCA | Life Cycle Analysis |

| MP | MegaPixels |

| MQTT | Message Queuing Telemetry Transport |

| NSPE | National Society of Professional Engineers |

| PBI | Prioritize Backlog Items |

| PC | Personal Computer |

| PESTEL | Political, Economic, Social, Technological, Environmental, Legal |

| ppm | parts per million |

| RAM | Random Access Memory |

| RH | Relative Humidity |

| ROHS | Restriction of Hazardous Substances Directive |

| SWOT | Strengths, Weaknesses, Opportunities, Threats |

| TCP | Transmission Control Protocol |

| TV | Television |

| UART | Universal Asynchronous Receiver/Transmitter |

| USB | Universal Serial Bus |

| Wi-Fi | Wireless Fidelity |

1. Introduction

Welcome to the exciting project dedicated to the creation of an innovative kitchen mushroom grower! In an era where thinking about sustainability and environmental responsibility is crucial. Today's environmental challenges are forcing a reconsideration of how waste is managed, in particular coffee waste resulting from everyday habits. It is in this context that this project was born, which aims to make an efficient composter accessible to everyone. The aim is to make the product of the composter useful.

This first chapter will introduce the project of CoffeeMush. Firstly the team will be presented in the next paragraph. Then the motivation, problem, objectives and requirements of the project are explained in the following sections. After that the functional tests that need to be done to test the prototype of the product will be explained. Finally, the project planning and structure concludes the introduction.

1.1 Presentation

This project was done by a group of 6 engineering students from different study fields and countries in Europe. The table 2 underneath presents team 1 who worked on CoffeeMush for the European Project Semester.

| Name | Origin | Background |

|---|---|---|

| Hugo Boulay | France | Mechanical Engineering |

| Nils Kötting | Germany | Mechanical Engineering |

| Noor Stapel | The Netherlands | Civil Engineering |

| Miro Heller | Belgium | Electromechanical Engineering |

| Roberto Lupo Agache | Spain | Computer Science Engineering |

| Vinyet Sorribas Sort | Spain | Mechanical Engineering |

1.2 Motivation

The team made two collective choices: the individual choice to join the European Project Semester (EPS) in Porto and the teamwise choice for the subject 'kitchen composter'. The choice for the EPS was made by every individual of the team because of collective reasons. First of all to broaden personal horizons by learning about different cultures, languages and environments. Secondly because the project is conjoined with students from different engineering backgrounds. Because of this everyone can learn a lot from eachother on technical aspects. Besides, the project is the biggest each teammember has ever done, which comes with new challenges and in the end results in skills like management-, teamwork- and communicationskills. Lastly our choice for Porto specificly is because the program specifies on projects contributing to the environment. Unlike other EPS programs, there is even a whole subject on environment.

The choice for the subject 'kitchen composter' was driven by a teamwise passion for preserving the environment and embracing a sustainable lifestyle. These are the key reasons fueling our commitment:

1. Waste Reduction: The mission is to significantly cut down the organic waste reaching landfills. Transforming coffee waste into compost helps shrink the carbon footprint and reduces the environmental impact of the daily waste.

2. Eco-Responsibility: The project revolves around raising awareness about eco-responsibility. Promoting the use of CoffeeMush, it aims to raise collective consciousness about the crucial role that individual choices play in the conservation of the planet.

3. Production of a useful product: The compost generated by kitchen composter bins nowadays inside the kitchen is mostly a useless product that cannot be used for further production of plants or food. That is because needed conditions for composting cannot be provided in a house without loosing commodity. The intention is to establish a sustainable cycle by reusing coffee waste for environmentally friendly agricultural practices.

4. Production of oyster mushrooms: Within the composting process, the machine manages to control and offer the best conditions for oyster mushrooms to grow. Those are actually the ones helping with the composting process besides being so delicious.

5. Learning and Awareness: Composting isn't just about waste management; it's an opportunity for education and interaction. The project, the seek is to educate the community on sustainable practices and encourage simple actions that positively impact the environment.

In conclusion, the motivation is rooted in the belief that every small action counts. The creation of this kitchen composter is a contribution to safeguarding nature for the generations to come.

1.3 Problem

The kitchen composter is a solution to a daily problem in today's society. This problem is that a lot of organic waste is not reused, only about 5 % [Erlantz Lizundia, 2024]. The aim is to contribute to society by making composting more accessible. The kitchen composters on the market today are quite good, but they are expensive and the product they make is not a fertiliser or otherwise useful. These aspects will be studied and developed to find a solution.

Another problem is how to grow mushrooms as quickly as possible. After focusing the project on a mushroom composter, it became clear that fresh coffee waste and a minimum amount of coffee waste were needed. This amount is around 200g.

An average family generates about 9 grams of coffee waste per day (assuming a family of 3-4 people and that each member drinks one cup of coffee per day)[Sara Sahai Marwah, 2021]. Therefore, an average family as it is known in our society cannot reach such quantities. This is why the product is targeted at large producers of coffee waste, such as restaurants, cafeterias, hotels or schools.

1.4 Objectives

The goal is clear: to develop a practical and innovative way to transform organic waste into a valuable resource. The composter goes far beyond being a simple container; it embodies the commitment to a sustainable lifestyle, waste reduction, and environmental education.

Why Composting? Beyond waste management, composting provides a unique opportunity to actively contribute to the preservation of the environment. By making this process available to everyone, a virtuous circle is created, turning food waste into a natural fertilizer that benefits the soil.

Although being good, traditional kitchen composters oftenly use to have some limitations. While they aim to compost organic waste, they can be slow, requiring patience as materials decompose. Moreover, there is a need for careful consideration of what is added, as certain items can disrupt the process or attract pests. In terms of sustainability, many regions already offer city-wide organic waste collection services, reducing the necessity for individual composting efforts, especially for those without access to a garden.

Recognizing these challenges, a more innovative approach was sought that would not only address the shortcomings of traditional composting but also provide a tangible benefit. Rather than limiting the project to pre-composting organic waste, a solution was considered that would harness the process to produce a valuable product. This gave rise to the idea of using coffee waste for a dual purpose: composting and mushroom cultivation.

By utilizing coffee waste as the substrate for mushroom growth during decomposition, the smart kitchen composter offers a unique advantage. Not only does it efficiently manage organic waste, but it also transforms it into a resource for cultivating nutritious and flavorful mushrooms [Florent Awedem Wobiwo, 2018]. This dual-purpose approach not only enhances the composting process but also provides a practical and rewarding outcome, aligning with sustainability goals while offering a compelling solution for households seeking to minimize waste and maximize resource utilization.

1.5 Requirements

As the composter takes shape, it is crucial to meet the project criteria and use them to guide the work. Let's look at what these requirements mean for the project:

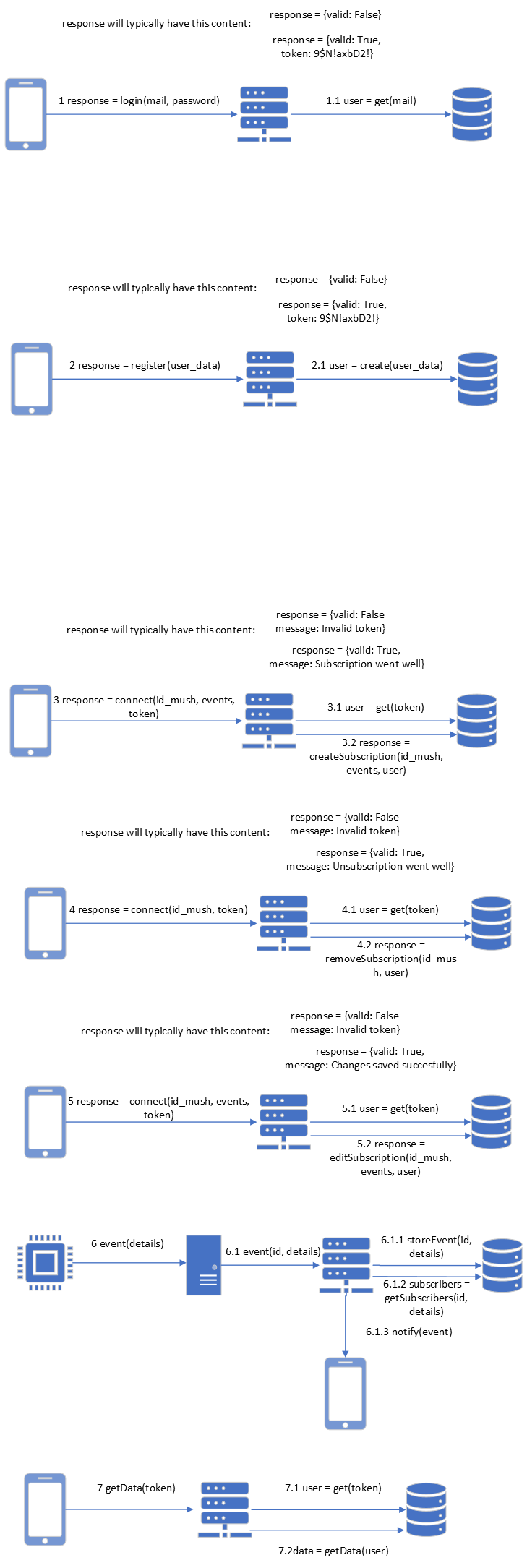

1. Acquire, store, and share monitored data: The system is intended to be intelligent and communicative. It will not only collect and store data efficiently but also make it easier for all involved to understand and exchange information about the composting process.

2. a. The budget is 100€ for the prototype. This budget must not be exceeded.

b. Use low-cost local hardware solutions: Affordability is important. The aim is to select equipment that is not expensive, to ensure that our composting solution is affordable for everyone. Sustainability must be accessible to all.

3. Use open-source software: It is committed to teamwork and transparency by using open-source software. This choice not only invites others to contribute but also allows the team to continuously improve and adapt as needed.

4. Adopt the International System of Units (NIST International Guide for the use of the International System of Units): Consistency is key. Adhere to internationally recognized measurement standards to ensure that the project communicates information clearly and consistently.

5. Comply with Directives: The following standards will be followed in order to ensure that the project is up to standard:

- Machinery Directive (2006/42/EC 2006-05-17): Prioritise safety in the design and use of machinery.

- Electromagnetic Compatibility Directive (2004/108/EC, 15-12-2004): Addressing electromagnetic interference.

- Low Voltage Directive (2014/35/EU 2016-04-20): Ensuring the electrical safety of our equipment.

- Radio Equipment Directive (2014/53/EU 2014-04-16): Efficient use of the radio spectrum.

- EU ROHS Directives: Choosing environmentally friendly and safe materials.

These are not just checkboxes; they are guiding principles. By paying attention to these criteria, not only do the technical standards are complied with, but also a sustainable, compliant and user-friendly composting solution is created.

6. The device should be sustainable. This can be realized in the use of the material, the use of power consumption and making the product recycleble and long-lasting.

7. The outcome of the device must be usefull.

8. The device should be automatic, smart and easy to use.

1.6 Functional Tests

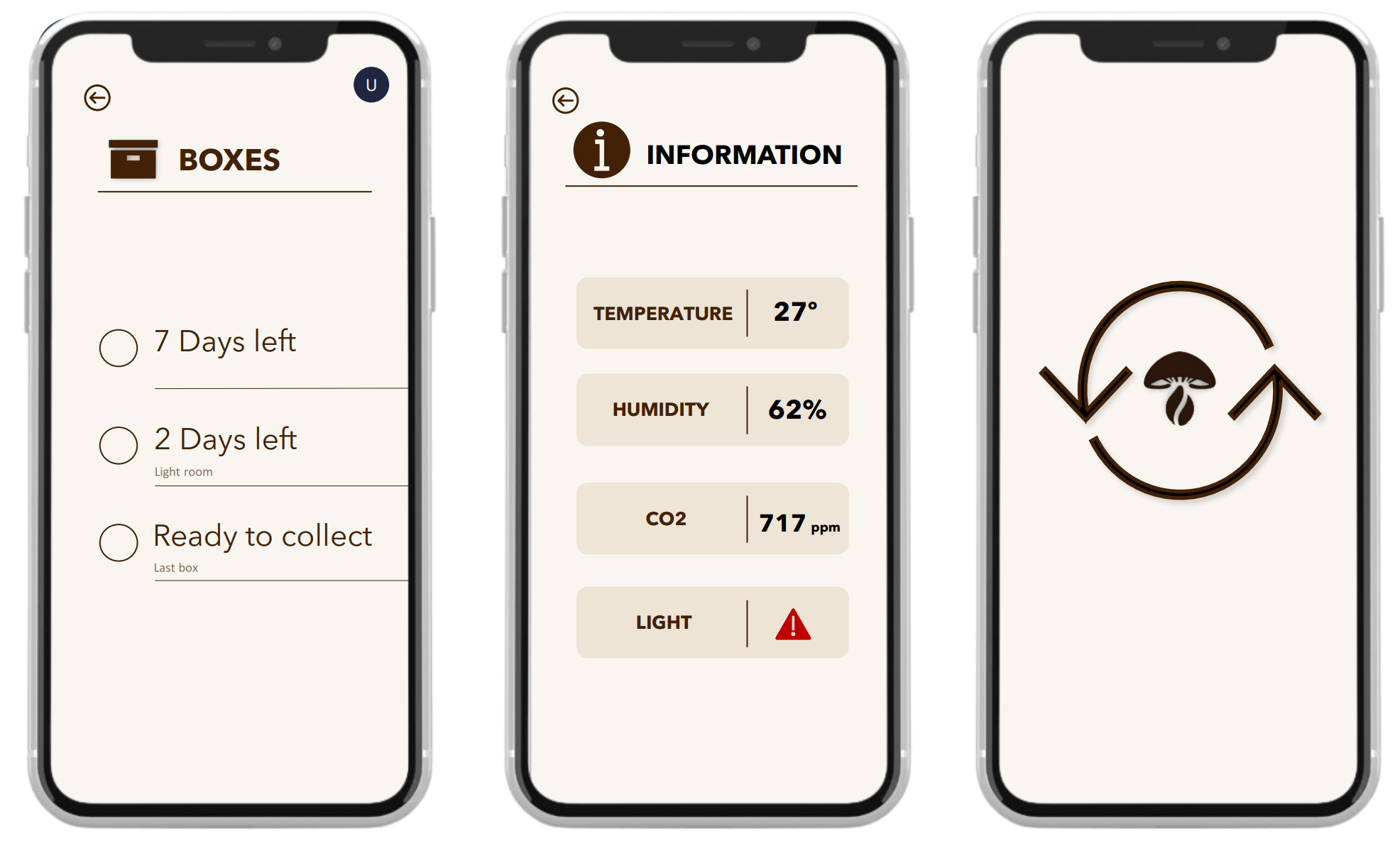

To make sure the product will work before it is brought onto the market, functional tests need to be done. For this, a prototype of the product will be made. The prototype will be tested on how well the mushrooms grow according to plan. Besides that, the sensors will be controlled and checked if any additions need to be made. Lastly, the app functions need to be checked. This can be done by checking if the information from the app corresponds with the actual status of the mushrooms in the product.

The functional tests of the prototype consist of:

- Sensor testing: Check if the AHT20 sensor receives information on the temperature and the humidity of the environment inside the box. Detection if there is water available in the water tank or not by the water float sensor.

- Hardware testing: See if the fan will blow if the climate is too humid and if the valve from the water tank will open if the climate is too dry.

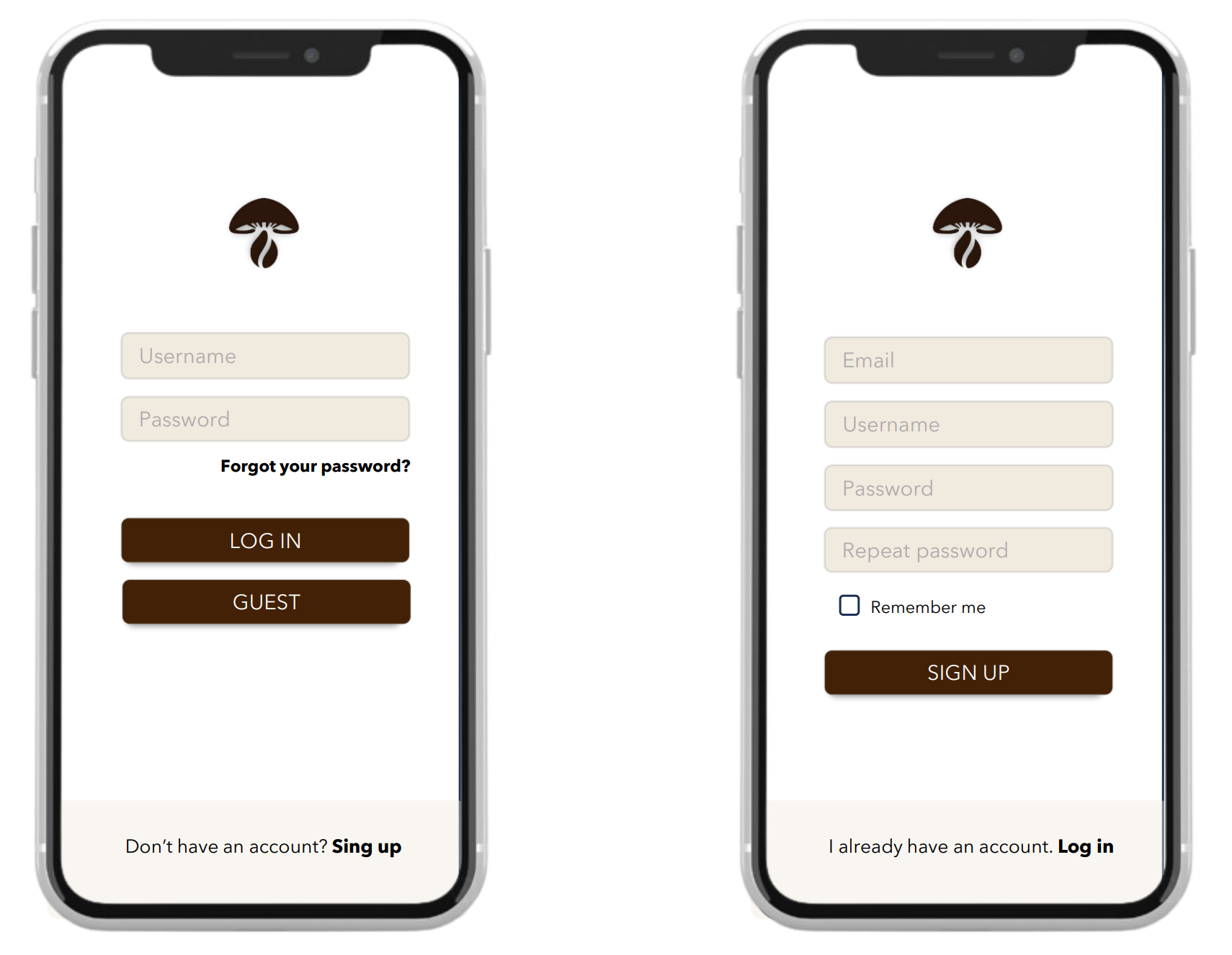

- Software testing: Check if the data of the AHT20 and the water float sensor will be transmitted to the application. So that the user will be able to read all of this information. If the user wants to receive a picture of the mycelium growth, the ESP32-CAM will be able to make the picture and send it to the application.

- Alarm testing: Send a notification to the user if there is no water available in the water tank. When it is not possible to regulate the temperature and the humidity inside the box properly, this will indicate that the composter is not located in a good environment.

For further information, please refer to Chapter 7 concerning the development of the prototype.

1.7 Project Planning

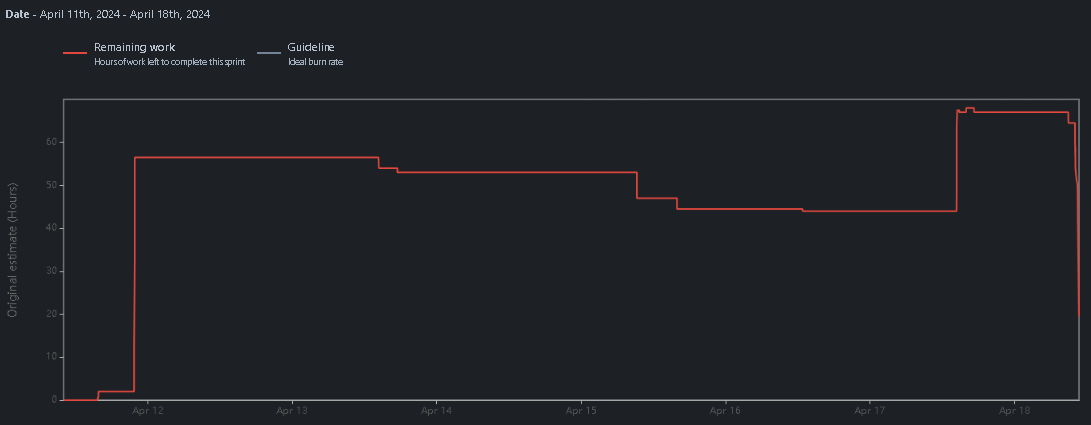

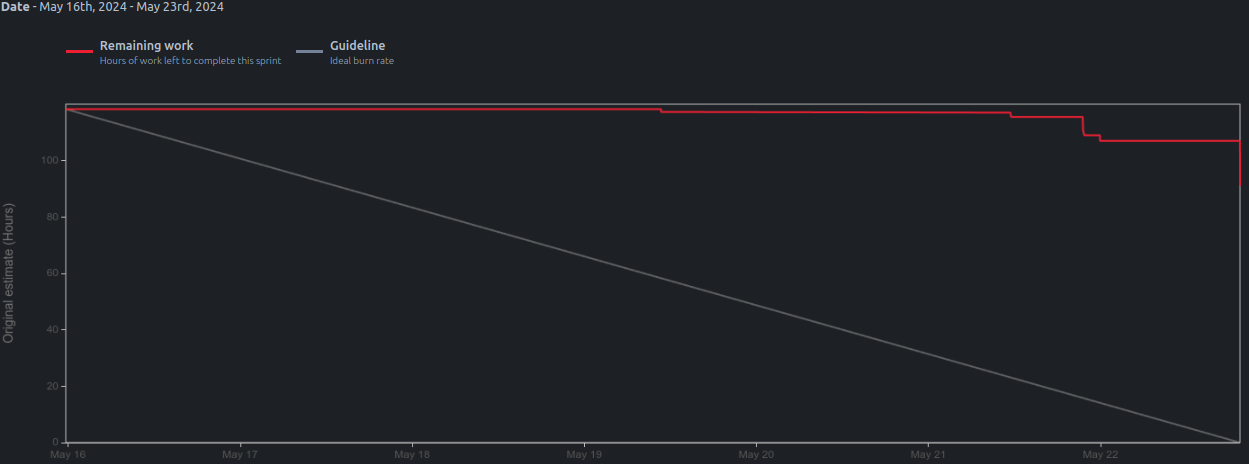

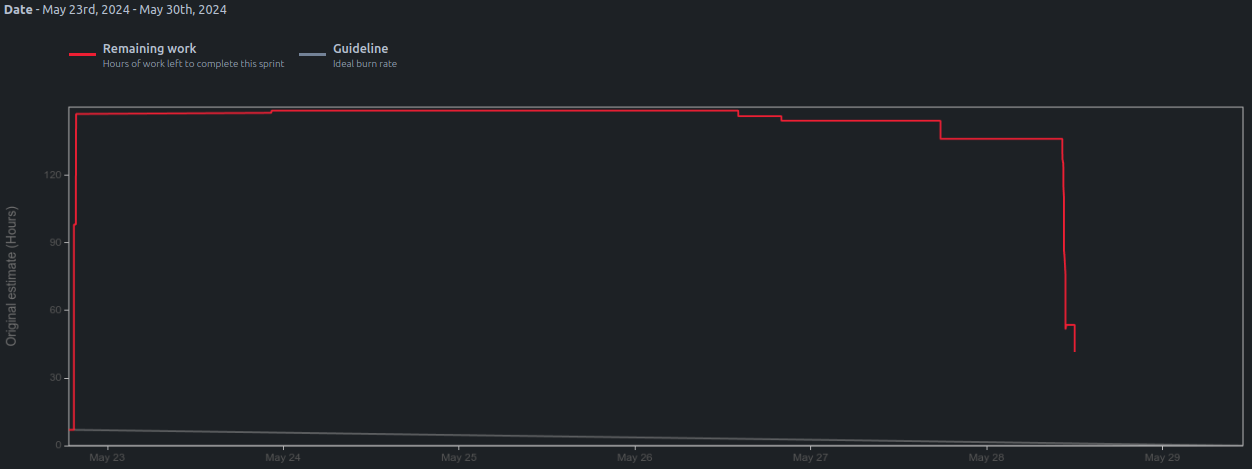

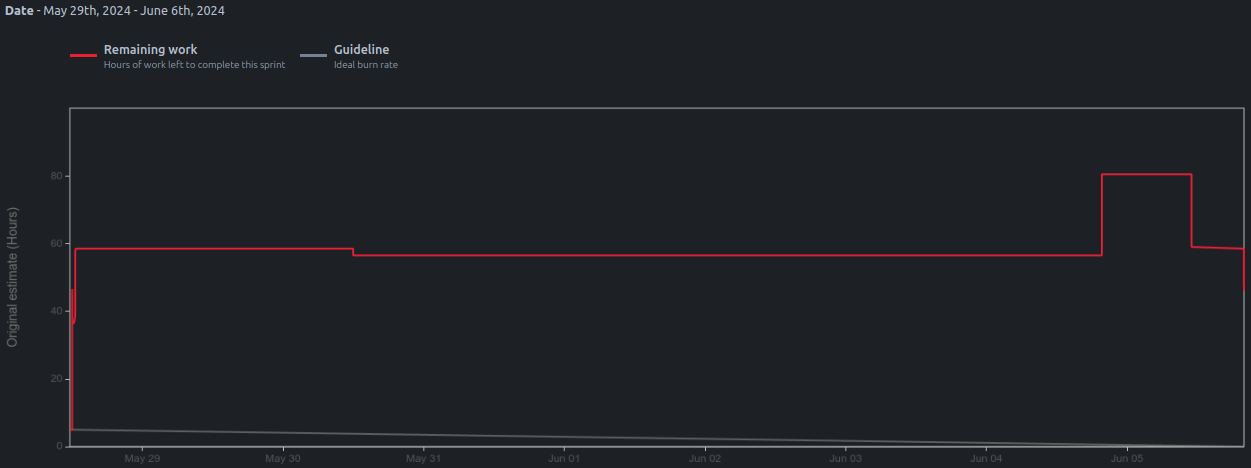

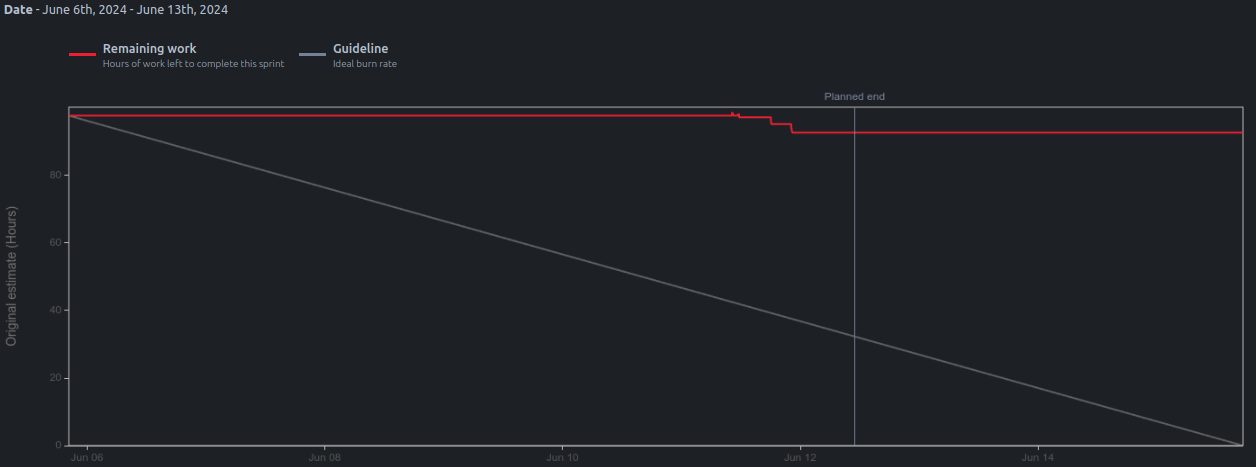

It is important to plan ahead for good teamwork and the best results for the project. This is done by project planning in Jira. In this program, different sprints are made for different weeks. In these sprints multiple tasks are made and assigned to different team members. In this way it is made sure that all team members take part in the project equally. This process is shown in Figure 1.

1.8 Report Structure

The following Table 3 shows the report structure and a brief description of the content.

| Number | Task | Description |

|---|---|---|

| 1 | Introduction | Introducing what this project is going to look like. |

| 2 | State of the Art | Explanation of the current kitchen composters on the market and background information. |

| 3 | Project Management | Overview of how the project was managed. |

| 4 | Marketing Plan | Explanation of the plan for putting our product on the market. |

| 5 | Eco-efficiency Measures for Sustainability | Explanation of the sustainable aspects that need to be taken into account in our project. |

| 6 | Ethical and Deontological Concerns | Explanation of the ethical and deontological aspects that need to be taken into account in our project. |

| 7 | Project Development | Explanation of the way the project was evaluated. |

| 8 | Conclusions | Concluding the main aspects of the project and the final product. |

| 9 | Bibliography | List of sources used. |

2. State of the Art

2.1 Introduction

This chapter covers the state of the art of kitchen composters and mushroom growers. The first paragraph is about the different composting methods. This paragraph shows the different composting concepts that are available. The next paragraph is about the kinds of kitchen composters and mushroom growers that are now on the market. Then, the best conditions for growing mushrooms are defined. Finally, this chapter will be ended by concluding the findings on the topics. The problems that are seen in the kitchen composters of today are pointed out and translated to aspects that need to be present in this project.

2.2 Composting methods

Nowadays, there are different composting methods that convert organic waste into compost. The most common are the following:

1. Open Air Composting: This method is considered warm composting and consists of piling organic waste on a surface that is in the open air. When little waste is used and little compost is generated, some people call it cold composting as this compost does not accumulate the same amount of heat.

2. Direct Compost: This is probably the oldest method. This method consists of digging a hole in the ground and putting the waste in the ground. The big disadvantage of this method is that the waste takes a long time to decompose unless it is chopped up.

3. Tumbler Composting: This method consists of putting the waste into a tumbler and turning the tumbler every day or every few days. The traditional method is to turn it by human power, but some mechanised systems are available that facilitate turning.

4. Worm Farm Composting: This method involves adding worms to organic waste, which aid in its decomposition. The worms produce concentrated excrements with lower nutrients and lower nitrogen compared to other composting methods, which makes it a good option. It also keeps rats away from the compost.

Worm Types

- South Australia Red Worms (Lumbricus rubellus) and Tiger worms (Eisenia fetida) under ideal conditions they rapidly reproduce 8 to 1500 worms

- Pontoscolex corethrunus or the Pheretima group

- Fishing worms are not good for composting.

5. EMO Composting: Also known as Effective Microorganisms, it is a method where Bokashi is mainly used. Bokashi is a process that, like traditional composting, converts organic matter into a nutrient-rich compost that improves soil quality. The main difference with traditional composting is that the input material is fermented by specialised bacteria, not decomposed. This method is generally used indoors and in order to filter unpleasant smells. There are some that use a carbon filter.

6. Combination Composting: Also known as Compost Composting Compost, it is a method that uses all composting methods. It does this by combining the 4 methods explained above: open composting, direct composting, vermicomposting and EMO composting. The major advantage is that all kitchen waste can be composted.

7. Commercial Composting: This method consists of mixing the waste with materials such as sawdust, pine bark, sand, ferrous sulphate and sometimes ammonia sulphate, all mixed together. It is mixed every 3 or 4 days and is ready in 6 weeks. It is made in large quantities. As it is commercial compost it does not have many nutrients but it is cheap.

8. Mechanical composting: This method involves using electricity to generate sufficient heat for composting and content rotation. The result is obtained in 24 hours and is semi-composted waste, so further composting will be required beforehand. [Vickib, 2023].

2.3 Composting concepts

Currently, there are different types of kitchen composters on the market. These come in different shapes, sizes, and can even be designed for certain food waste to create plant-specific fertilizers. This paragraph shows the different concepts that are available or developed at the moment.

1) Modular composter - ORRE

This kitchen composter is built from modules, seen in Figure 2 below. Thanks to these modules, it takes up little space and allows a huge volume of waste to be processed. A built-in fan, which pushes the air inside, guarantees good oxygenation for the compost (it is important that the correct processes take place), and the carbon filter prevents unpleasant odors.

2) Tea-Composter - SHiBUi

This kitchen composter is specifically designed for tea waste, as the tea grounds are natural, organic matter, they increase nutrient levels and improve soil quality as they decompose. It is designed to be for household use since around 80 % of the total tea produced in India is consumed by the domestic population. The idea of this composter is to create a small ecosystem and since plants are in direct benefit, including them in the design as a part of a complete cycle. This cycle can be seen in Figure 3.

3) Automated exotic mushroom growing - Fancom

Cultivating exotic mushrooms is a delicate balancing act. For years, the demand for exotic varieties of mushrooms has been growing, driven by the increasing trend of eating healthy and natural food. Oyster mushrooms, Enoki and Shiitake are a few examples of popular exotic mushrooms. These variants can be cultivated with the help of automated mushroom-growing systems.

Nowadays there exist some machines that automatically create the optimal cultivation conditions for mushrooms with a computer. It also takes the outside conditions into account. The system for growing exotic mushrooms continuously monitors important climate parameters such as substrate, air temperature, humidity and CO₂-percentage. It always ensures the correct balance. If any abnormalities are detected, the computer will respond rapidly, but, at the same time, gradually. The result is a stable climate with hardly any fluctuations in the cultivation conditions. Users can benefit from higher production and better quality.

One example of these automated machines is the fancom machine, which can be seen in Figure 4.

2.4 Kinds of kitchen composters

This paragraph explains the different composters and their advantages and disadvantages. In this way, they can be compared to each other and the important aspects of this composter can be defined.

1) Reencle composter

This composter works silently 24 hours a day, so there is no need to wait until you are finished with the previous food scraps. You simply take out the fertilizer when it looks full. The composter can be seen in Figure 5 below. A 3-layer filter system guarantees odor-free composting. This composter is equipped with a non-contact motion sensor, can survive in high acid and high salinity environments, and operates quietly below 28 dB. This sound is exceptional for an actuator.

2) Mill

The composter from the brand ‘Mill’ is a modern composter, which looks like a futuristic bin, as seen in Figure 6.

This product has a high price: 939 €. This makes it mainly accessible to the high financial class. Another disadvantage is that the product can be used as a chicken food, but not for any other use.

The advantages of Mill are the leak of sound and smell and the composting time. The sound (42 dB) and composting time (2.5 hours) are low. The smartness and smell are quite good as well. Though compared to other smart kitchen composters this is developed about the same. The smell is minimized by odor filtration, in which the filters have to be renewed every year [Mill Industry, 2024].

3) Lomi

The kitchen composter from Lomi is less expensive than Mill, but still quite a lot: 599 €. It is smaller than the one from Mill, but the smell, time and smartness is about the same. A picture can be seen in Figure 7.

A disadvantage of this product is that the product that comes out of the composter is useless concentrated compost. So the user needs to still throw away the waste. Besides that, the time it takes to compost is about 12 hours, which is really long compared to the first to products [Pela, 2024].

4) Foodcycler

The Foodcycler kitchen composter is quite similar to the kitchen composter from Lomi. The exterior looks similar as well. It can be seen in Figure 8.

However, this product shows some more advantages: the price is lower and the compost time is shorter. The price is 500 € and the compost time is 5 hours. The only aspect that is less than the other products is the smartness: this product is more traditional and does not show innovative aspects like short compost time or a filtration system [Foodcycler, 2023].

5) Skaza

This product, which can be seen in Figure 9, is the cheapest of all composters that are compared in this chapter. Though it is not that smart and innovative. A big disadvantage that comes with this is the long time it takes to compost. The composting time is 2 weeks for this product, which means that when the user fills the composter one day, the user cannot use it for the next two weeks [Amazon, 2024].

6) Beyondgreen

This product is the cheapest of these 6 products after Skaza: 409 €. All natural foods can be composted, like the other products. Beyondgreen has a lot of disadvantages though. First of all, the compost time is quite long: 1 week. Furthermore, the product is a useless compost that cannot be used for any other functions. Thirdly, the smell sound and smartness is not of high quality. There are no measures taken to improve this, compared to the traditional way [beyondGREEN biotech, 2024], [Richard Baguley, 2022].

7) Mella Mella is a system for mushroom growing specifically. There are three different boxes, in which three different types of mushrooms can be grown. The product can be seen below in the figure 11.

The user has to install the device and select the humidity and fan speed. After this, the user has no actions that need to be done, apart from filling the water tank once a week. The smell and noise are minimized, though not zero. There is always a background noise and the process takes long, which is a disadvantage. The smell is minimized by fans, which reviewers say works well. The device is quite smart, it regulates the humidity and airflow, but it does not have an app that shows you how long until the mushrooms are done [Jill Sherman, 2023].

8)Shrooly This device is quite similar to Mella, though a little smaller. There is only room for one type of mushroom to be grown. This can be seen below in the figure 12.

Though mostly different spores are added, so some kind of mixture arises. The input is not waste, but a product from Shrooly, called pods. This is similar to Mella. The pods can grow one to three batches of mushrooms. A disadvantage is that these pods need to be bought for every use of the device, they cost 12 € per pod [Ben Coxworth, 2022].

In the Table 4, the six different kitchen composters and the two mushroom growers are compared. They are compared on the aspects ‘cost’, ‘waste input’, ‘product output’, compost time’, ‘smell’, ‘sound’ and ‘smartness’. Cost, compost time and sound can mostly be measured in quantity with units, but sometimes there is no quantity known.

| Name | Cost [€] | Waste / Input | Product output | Compost time | Smell | Sound [dB] | Smartness |

|---|---|---|---|---|---|---|---|

| Reencle | 585 | Natural food | Grasscompost | 2 h | Filter system | 28 | Smart sensors |

| Mill | 939 | Natural food | Chickenfood | 2.5 h | Filter system | 42 | Smart sensors |

| Lomi | 599 | Natural food | Useless concentrated compost | 12 h | Filter system | ‘quiet’ | Smart sensors |

| Foodcycler | 500 | Natural food | Useless concentrated compost | 5 h | Filter system | ‘quiet’ | No additional aspects |

| Skaza | 90 | Natural food | Useless compost | 2 weeks | No system | 0 | No additional aspects |

| Beyongreen | 409 | Natural food | Useless compost | 1 week | No system | Not quiet | No additional aspects |

| Mella | 447 | Bought product | Mushroom | 2 weeks | No system | Not quiet | No additional aspects |

| Shrooly | 419 | Bought product | Mushroom | 2 weeks | No system | Not quiet | No additional aspects |

2.5 Conditions for growing mushrooms

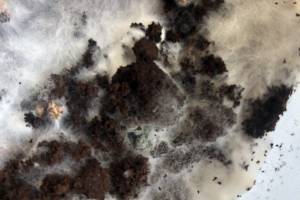

Mushrooms are mostly grown in buckets with holes for ventilation and oxygen. They are grown by combining coffee grounds with mushroom spawn and water. The coffee ground needs to be heated (60-80 °C) to kill organisms first. This does not need to be done if the coffee was already heated for making a drink. Afterward, it should be cooled to room temperature. Only after that can you add the mushroom spawn to the coffee ground, the optimal temperature for this is room temperature (18-24 °C). It takes two weeks to colonize the spawns, in this time they should be in the dark to prevent fruiting. During this period, you also need to maintain a humidity of 85-95% for growing oyster mushrooms [Drew Swainston, 2023] [Desiree Vilar, 2023]. The coffee ground must be completely colonized by the spawns to start fruiting. The coffee cannot be older than 24 hours, otherwise mold will start growing on it. At the end of the growing cycle, the composted grounds can be used to enrich the soil for your own plants [Elliot Webb, Niall Cullen, 2023] [Adam Sayner, 2023].

2.6 Conclusion

The kitchen composters that are on the market nowadays show some problems. This can be concluded from the table 4. This project aims to solve these problems in order to make the purchase of kitchen composters more attractive. It is of interest to clarify those problems to be able to solve them.

First of all the product that comes out of the composters that are on the market nowadays are not fertilizers. The products are dried and compact, but not really useful to fertilize plants or grow food. The Mella and Shrooly grow mushrooms, which is a useful product. The disadvantage of them is that the input needs to be bought at their company, it is not waste from people themselves.

Second, kitchen composters are quite expensive these days, and it is difficult to get rid of the composter's leftovers. Due to the high costs, it is not accessible for lower-class citizens. Next to that, it is hard to sell the additional products people create by using the composter to local services. These two aspects could be combined to find a problem: selling the product of the composter can make the composter financially more accessible.

Based on this state-of-the-art study, the team decided to adopt techniques to obtain the best conditions for mushrooms so that they can be grown as quickly as possible. The smart device must be sustainable, affordable and innovative. Multiple factors had to be taken into account: the noise, smell, size, method, prize and product of the composter. From the research on the state of the art, it can be concluded that the price is really high (about 500 €) for a smart kitchen composter. Another aspect to note is the composter product: the usefulness of this product is, in most cases, not so high. It is often compost that cannot be used, for example, to grow new food. Often it is waste or animal food. This is something the team wants to take into account for the project. It would be good if the product is a type of food that can be eaten or used in the kitchen. The mushroom-growing devices that are on the market now need input products that need to be bought from their company. CoffeeMush thrives to make mushrooms from actual waste, which contributes to the environment and affordability.

In the next chapter, the project will be managed to be able to perform the tasks within the project as good as possible. The management chapter shows how the project is tackled, how the tasks are divided and how the product and project will be finished on time for the deadline with the best results.

3. Project Management

3.1 Scope

In order to be more precised about the scope of the project than in the introduction, from a project management point of view, the following objectives are to be achieved, also illustrated in Figure 13:

- Initial research: First of all, initial research has to be done to find out the state of the art. At this point, the marketing analysis can be started, which will provide new strategies to innovate by following ethical and sustainable ideas.

-

Project Planning: Once the product has been defined, the development process begins to be planned, taking into account the milestones of the project as a whole.

-

Design on the final product: Whole schematics drawings and materials specifications regarding the physical creation of the final product. This will be followed by the 3D model, the product video presentation, paper, poster and manual.

-

Design and creation of the prototype: Which has to be actual proof that the product works. It starts with a simple cardboard model, and ends with a functional prototype connected to the server and an android device with the app installed.

-

Final Report and Presentation: As it follows it contains all the required documentation on the development process as well as the presentation of the main parts.

3.2 Time

Table 5 shows the deadlines the team has set for the project.

| Task | Deadline |

|---|---|

| Blackbox | 2024-03-06 |

| System Diagram | 2024-03-06 |

| Structural Drafts | 2024-03-06 |

| Project Backlog | 2024-03-08 |

| Global Sprint Plan | 2024-03-08 |

| Release Gantt Chart | 2024-03-08 |

| List of Components and Materials | 2024-03-13 |

| System Schematics | 2024-03-20 |

| Structural Drawings | 2024-03-20 |

| Cardboard scale model | 2024-03-20 |

| Interim Report | 2024-04-07 |

| Presentation materials | 2024-04-07 |

| 3D model video | 2024-04-17 |

| Final List of Materials | 2024-04-23 |

| Refined Interim Report | 2024-04-30 |

| Packaging solution | 2024-05-15 |

| Functional Tests | 2024-05-28 |

| Final Report | 2024-06-16 |

| Final Presentation materials | 2024-06-16 |

| Video | 2024-06-16 |

| Paper | 2024-06-16 |

| Poster | 2024-06-16 |

| Manual | 2024-06-16 |

| Final Presentation | 2024-06-20 |

| Suggested corrections | 2024-06-25 |

| Prototype and user manual handing | 2024-06-27 |

3.3 Cost

Regarding the project costs, the workers' salaries and the budget are considered for the materials used. Other costs such as goods or services used, like workspace, electricity, and others, are not taken into account. Thank you though, to ISEP for allowing the team to use them.

Therefore, the average cost of hiring an engineer in Portugal amounts to 2217 € [Glassdoor, 2024]. Taking into account that the team consist of 6 workers for 5 months and adding the 100 € budget, the total cost is 66.610 €.

3.4 Quality

Considering that the project can be splitted in different independent parts, the quality metrics to be applied for each of them will be specified.

3.4.1 CoffeeMush Quality

The metrics are shown here in terms of the physical product itself:

- Durability: Ensure that the composter is built to last and withstands regular use over time.

-

Functionality: Verify that the composter effectively converts coffee waste into mushroom growth and fertilizer.

-

Ease of Use: Assess how user-friendly the composter is, considering factors like setup, maintenance, and harvesting.

-

Safety: Ensure that the composter is safe to operate and doesn't pose any risks to users or the environment.

-

Environmental Impact: Measure the environmental benefits of the composter, such as reduced waste and sustainable mushroom production.

-

Material Quality: Evaluate the quality of materials used in the composter's construction for longevity and eco-friendliness.

3.4.2 Documentation Quality

The metrics are shown below taking into account all the project documentation (including the Report, schematic drawings, documents, user guides…):

-

Clarity: Ensure that documentation (user manuals, assembly guides, etc.) is clear and easy to understand.

-

Completeness: Verify that all necessary information is included in the documentation, covering setup, usage, troubleshooting, and maintenance.

-

Accuracy: Ensure that information provided in the documentation is accurate and up-to-date.

-

Consistency: Maintain consistency in language, formatting, and terminology throughout the documentation.

-

Accessibility: Ensure that documentation is accessible to all users, including those with disabilities, by providing alternative formats if needed.

3.4.3 Marketing Quality

Metrics relating to all marketing and promotional material (including logo, slogan, brochure, promotional video…) are shown in this section:

-

Brand Identity: Assess the alignment of branding elements (logo, slogan) with the product's value proposition and target audience.

-

Visual Appeal: Evaluate the aesthetic quality of promotional materials, including videos, images, and graphics.

-

Message Effectiveness: Measure the effectiveness of marketing messages in communicating the product's benefits and unique selling points.

-

Engagement: Monitor audience engagement metrics (views, likes, shares) for promotional content across various platforms.

-

Consistency: Ensure consistency in branding and messaging across all marketing channels and materials.

3.4.4 Android Application Quality

At last but not least, all the metrics for the android application are defined:

-

Functionality: Ensure that the app functions as intended, providing all necessary features and capabilities.

-

Performance: Evaluate app performance in terms of speed, responsiveness, and resource usage.

-

User Experience (UX): Assess the app's user interface design and navigation for ease of use and intuitiveness.

-

Compatibility: Verify that the app is compatible with a wide range of Android devices and operating system versions.

-

Security: Ensure that user data is secure and protected against unauthorized access or breaches.

-

Bug-Free: Monitor and address any bugs or issues reported by users through regular testing and updates.

3.5 People

In every project, an intricate network of stakeholders plays a pivotal role, each with varying degrees of influence and significance. The success of any project depends upon a comprehension of the involved people and their roles. Within this particular project, a diverse array of stakeholders contributes to its advancement and ultimate fruition.

At the forefront stands the dedicated project team, serving as the driving force behind the development of the prototype and the overall progress of the initiative. Charged with the task of translating vision into tangible reality, this team wields a profound impact on the project's trajectory and outcome.

Further contributing to the project's evolution are the esteemed educators from EPS, whose invaluable feedback and financial support are instrumental in guiding its course. Endowed with a wealth of knowledge and experience, their input not only enriches the project's development but also ensures its alignment with educational objectives and fiscal feasibility.

In addition to these stakeholders, suppliers also play a crucial role in the project's success. Suppliers provide the necessary materials, components, and resources essential for the project's execution. Their reliability, quality of products, and timely delivery directly impact the project's progress and outcomes. Building strong partnerships with suppliers fosters collaboration and ensures a smooth flow of materials, contributing to project efficiency and effectiveness. Thus, acknowledging and nurturing relationships with suppliers is paramount for achieving project goals and delivering value to stakeholders.

Finally, customers must be taken into account. Their importance lies in their indirect but substantial influence. Ultimately, our product responds to their needs, so their satisfaction is essential to our success. Without them, our efforts would lack meaning and viability.

3.6 Communications

At the core of the communication strategy lies the primary channel: the WhatsApp group, which serves as a dynamic hub for instantaneous communication among team members, transcending geographical barriers and facilitating seamless collaboration regardless of the locations. This platform enables the team to swiftly disseminate vital information, share updates, and address pressing matters in real-time, fostering agility and responsiveness in the operations.

Furthermore, the interactions extend beyond the virtual realm, finding meetings in the classroom environment. Given the frequency of the face-to-face encounters, the opportunity is taken to participate in daily discussions and meetings during the breaks between classes. This in-person communication not only promotes team cohesion but also ensures alignment and clarity in the collective project work.

While WhatsApp serves as the primary communication channel, other digital platforms are also leveraged to enhance collaboration efforts. Microsoft Teams plays a key role as a centralised repository for storing essential documents and files, facilitating access and sharing among team members. In addition, Jira's collaboration capabilities integrate communication into task workflows, forcing the team to discuss tasks once they are completed. This ensures complete documentation and promotes transparency, allowing team members to stay informed and engaged throughout the project lifecycle.

3.7 Risk

Risk management is a proactive approach to anticipating and addressing potential challenges, whether positive or negative, that may arise during a project. It involves identifying, assessing, and prioritizing risks to develop strategies for mitigating adverse impacts and capitalizing on opportunities. By continuously monitoring and controlling risks throughout the project lifecycle, teams can adapt swiftly to changing circumstances. Key components of risk management include:

-

Risk Identification: Continuously identifying potential risks throughout the project lifecycle to anticipate and prepare for potential challenges.

-

Risk Evaluation: Assessing the likelihood and potential impact of identified risks on project outcomes, both quantitatively and qualitatively, to determine appropriate mitigation strategies. Probabilities and time frames (long, medium or short term) are also considered.

-

Risk Handling: Developing strategies to address both negative risks (threats) and positive risks (opportunities). For negative risks, efforts may focus on avoidance, mitigation, or transferring the risk to other parties such as insurance companies. Positive risks may be exploited, enhanced, shared, accepted, or ignored depending on their potential benefits.

-

Risk Monitoring and Control: Continuously monitoring and controlling identified risks throughout the project to ensure that mitigation strategies remain effective and to respond promptly to any changes or new risks that may arise.

By systematically managing risks, teams can enhance their ability to navigate uncertainties and increase the likelihood of project success in an ever-changing environment. Table 6 shows the main risks that are considered for the project.

| Risk | Timeframe | Probability | Impact | Handling | Monitoring |

|---|---|---|---|---|---|

| Malfunctioning of the composter machine, leading to suboptimal conditions for mushroom growth. | Long-term | 30 % | 90 % | Having different kinds of sensors for monitoring such as temperature, air quality, light, pictures… | Monitoring in the app and having alerts for non logical happening things |

| Inadequate monitoring system in the application, resulting in inaccurate data collection or failure to send alerts. | Long-term | 30 % | 90 % | Making strict testing on as many use cases as possible. | Saving all things in the logs besides the application and database |

| Shortage of coffee waste or oyster mushroom seeds due to fluctuations in supply or unexpected demand. | Long-term | 50 % | 90 % | Migrate this responsibility to the user. Anyways it is offered the facility of buying/selling those through the application | Saving for each user/machine the amount of coffee waste, mushrooms produced… |

| Dependence on specific suppliers for essential components or materials, leading to delays or disruptions in production. | All terms | 10 % | 40 % | Having different suppliers options just in case | No need |

| Limited demand for coffee waste composters or oyster mushrooms, resulting in low sales and revenue generation. | Long-term | 10 % | 80 % | Accept/Be aware of coffee use and not produce more composters than needed | No need |

| Competition from alternative composting methods or mushroom cultivation techniques. | Long-term | 30 % | 70 % | Analyzing competitors and planning marketing strategies for innovation and improvement | No need |

| Lack of proper permits or licenses for selling compost, mushrooms, or fertilizer, hindering business operations. | Long-term | 20 % | 40 % | Accept/Be aware of legal conditions for each region | No need |

| Overestimation of project costs or underestimation of expenses, leading to budget overruns and financial strain. | Mid-term | 30 % | 70 % | Meticulous calculations before doing each step | No need |

| Difficulty in securing funding or investment for the project, limiting its ability to scale or expand. | Short/Mid-term | 40 % | 70 % | Being as convincing and innovative as possible | No need |

| Human error during the operation of the composter machine or application, resulting in production delays or errors in data analysis. | Short/Mid-term | 50 % | 60 % | Procuring having things done a reasonable time before the deadline | No need |

| Potential contamination of mushrooms or compost with harmful pathogens or toxins, posing health risks to consumers. | Long-term | 20 % | 90 % | Having the process as controlled as possible | Asking feedback each time a set of mushrooms are collected through the application |

| Accidents or injuries related to the operation of the composter machine or handling of materials. | Long-term | 10 % | 60 % | Designing it as carefully as possible considering users might not use it as expected | Having one department or folder with all related informations |

| Environmental factors such as temperature fluctuations or pest infestations affecting mushroom growth or composting process | Long-term | 30 % | 80 % | Designing the product as self-dependent as possible, isolate it from outside conditions being as efficient and sustainable as possible. | Monitoring which inside-machine conditions differ the most from the outside ones |

3.8 Procurement

To realize this project, in addition to the deliverables already mentioned, it is mandatory to carry out a proof of concept in the form of a prototype. For the construction of the prototype the given budget is 100 €. Given the constraints imposed by limited financial resources, a strategic approach to recruitment is adopted, being cost-consciousness and selective.

In light of the budgetary constraints, the team aims to maximize the utilization of existing resources by adapting the functional prototype to incorporate the most cost-effective materials readily available. Drawing upon ingenuity and creativity, pre-existing components and materials are identified and reused to suit project requirements, minimizing cost without compromising functionality or quality.

Furthermore, a priority is the selection of electronic elements and programming languages based on the collective expertise of the team members in these domains. By leveraging the existing proficiency and familiarity with certain technologies, the risk of costly errors or inefficiencies is mitigated, ensuring optimal utilization of resources and expediting the development process.

To optimize logistical efficiencies and reduce transportation costs, the team consolidates the procurement efforts by sourcing all electronic materials from a single supplier: Digikey, renowned for its competitive pricing and comprehensive product offerings. This strategic partnership not only streamlines the supply chain operations but also minimizes lead times and enhances cost-effectiveness, maximizing the value derived from the limited budget.

For non-electronic materials, a similar cost-conscious approach is used, opting to purchase from affordable physical stores within Porto, such as Continente and Ikea. By prioritizing affordability and accessibility, the procurement strategy is optimized to ensure a prudent allocation of resources, while meeting project requirements.

Additionally, capitalize on the resources available through the educational institution ISEP, by leveraging borrowed components to complement procurement efforts further and alleviate financial burdens.

In essence, procurement strategy represents a sensible balance between resource utilization, cost awareness and strategic sourcing, underpinned by a commitment to maximizing value and minimizing expenditure. By aligning procurement practices with project constraints and objectives, a solid foundation for success is laid, while optimizing resource utilization and mitigating financial risk.

3.9 Stakeholders Management

Defining stakeholders is a critical step in understanding the various parties involved in a project. By identifying stakeholders and their respective needs, project objectives, priorities, and resource allocation can be effectively determined. This process also aids in identifying user needs, thereby enhancing both the quality of work and the final product. According to ISO standards, stakeholders are defined as individuals or groups with an interest in the decisions or activities of an organization. In Table 7 stakeholders are listed along with their functions, interests, and levels of influence.

| Stakeholder | Function | Influence | Interest |

|---|---|---|---|

| Project team member | Working on the project | 5 | 5 |

| Teachers | Control and guide the project | 5 | 4 |

| Suppliers | Supply with needed materials | 2 | 2 |

| Customers | Buy and use the product | 4 | 4 |

By plotting the stakeholders on the grid in Figure 14, project managers can gain insight into how to work effectively with each stakeholder group. Stakeholders are often categorized into four quadrants:

High Interest, High Influence: Stakeholders in this quadrant have both a high level of interest in the project and significant influence over its outcomes. They require close communication and engagement to ensure their needs are addressed and their input is considered.

High Interest, Low Influence: These stakeholders are highly interested in the project but have limited influence over its direction. While their input may be valuable, their impact on decision-making may be minimal. It's important to keep them informed and involved to maintain their support and address any concerns they may have.

Low Interest, High Influence: Stakeholders in this quadrant have significant power to influence the project's outcomes but may have limited interest or awareness of the project. While their involvement may be sporadic, it's essential to engage them strategically to gain their support and leverage their influence when needed.

Low Interest, Low Influence: Stakeholders in this quadrant have minimal interest in the project and little to no influence over its outcomes. They may require minimal communication and involvement unless their interest or influence changes over the course of the project.

3.10 Project Plan

The optimal sprint duration and plan is defined below using Global Sprint Plan Table 8.

| Sprint | Start | Finish | Status |

|---|---|---|---|

| 1 | 29/02/2024 | 06/03/2024 | Done |

| 2 | 07/03/2024 | 13/03/2024 | Done |

| 3 | 14/03/2024 | 20/03/2024 | Done |

| 4 | 21/03/2024 | 03/04/2024 | Done |

| 5 | 04/04/2024 | 10/04/2024 | Done |

| 6 | 11/04/2024 | 17/04/2024 | Done |

| 7 | 18/04/2024 | 24/04/2024 | Done |

| 8 | 25/04/2024 | 01/05/2024 | Done |

| 9 | 02/05/2024 | 15/05/2024 | Done |

| 10 | 16/05/2024 | 22/05/2024 | Done |

| 11 | 23/05/2024 | 29/05/2024 | Done |

| 12 | 30/05/2024 | 05/06/2024 | Done |

| 13 | 06/06/2024 | 12/06/2024 | Done |

| 14 | 13/06/2024 | 19/06/2024 | Doing |

| 15 | 20/06/2024 | 26/06/2024 | To do |

The table below shows the project backlog, including all relevant tasks/deliverables, using Project Backlog Table 9. It prioritizes all backlog items (PBI), keeping higher priority items at the top, and lower priority at the bottom.

| Summary | Issue key |

|---|---|

| Sprint 8 stand-up dailies | CK-440 |

| Product Design | CK-404 |

| Sprint 7 stand-up dailies | CK-400 |

| Electronic design | CK-391 |

| Sprint 6 stand-up dailies | CK-373 |

| Meetings | CK-368 |

| Final List of materials - 23/4/2024 | CK-366 |

| Teachers feedback on Interim report | CK-352 |

| Interim presentation | CK-346 |

| Color Palette | CK-336 |

| 3D Model video | CK-319 |

| Rail for rolling down system with stop | CK-310 |

| Sprint 5 stand-up dailies | CK-306 |

| Interim presentation 11/04/2024 | CK-303 |

| Sprint 4 Stand-up dailies | CK-297 |

| Ventilation Design | CK-270 |

| Market Analysis 03/04 | CK-237 |

| Interim Report 07/04 | CK-226 |

| Mushroom recognition model | CK-222 |

| Manual | CK-221 |

| Poster | CK-220 |

| Paper | CK-219 |

| Project video | CK-218 |

| Final presentation | CK-217 |

| Final report | CK-216 |

| Functional tests | CK-215 |

| Packaging solution | CK-214 |

| Presentation 11/04 | CK-212 |

| Outside with solar panel | CK-211 |

| Coffee capsules opener | CK-210 |

| Share fertilizer/mushrooms/waste in app | CK-209 |

| Anti-smell | CK-208 |

| Smaller Design | CK-207 |

| API | CK-197 |

| Database | CK-196 |

| Management Tasks | CK-101 |

| Wiki report (First idea) | CK-58 |

| Composting process | CK-10 |

| Cardboard Model | CK-7 |

| Materials | CK-6 |

| App | CK-5 |

| “Marketing name, slogan, logo and flyer” | CK-4 |

| First electronic design | CK-3 |

| First design | CK-1 |

Below shows an identification key project deliverables (when they will be started and completed) and build a release Gantt chart. See Figure 15 for inspiration.

3.11 Sprint Outcomes

The results of each sprint are shown below. Although the initial results may not meet the desired standards due to the limited experience of the team, there are noticeable improvements as the project progresses.

In agile project management, particularly in Scrum, velocity refers to the amount of work a team completes during a sprint. It's a measure of how efficiently the team is delivering on their commitments.

Planned Velocity is the velocity that the team anticipates achieving for a particular sprint. It's based on factors such as historical data, team capacity, and the estimated complexity of the tasks or user stories planned for the sprint.

Real Velocity, on the other hand, is the actual velocity the team achieves during the sprint. It reflects the team's ability to execute their planned work within the sprint timeframe, taking into account any unforeseen challenges, dependencies, or changes that may have impacted their productivity.

Comparing Planned Velocity with Real Velocity provides valuable insights into the team's performance and helps identify areas for improvement. If the Real Velocity consistently falls short of the Planned Velocity, it may indicate that the team is overcommitting or encountering obstacles that impede their progress. Conversely, if the Real Velocity exceeds the Planned Velocity, it suggests that the team is delivering more efficiently than expected.

Analyzing this comparison enables the team to make informed decisions for future sprints, such as adjusting their capacity planning, refining their estimation techniques, or addressing any bottlenecks that may be hindering their productivity. Ultimately, the goal is to optimize the team's performance and ensure they consistently deliver value to the project stakeholders. This comparison can be seen in table 10. The x indicates that the sprints have not yet started. The team started in sprint 2. But in sprint 2 the time was not recorded, because the team only learned it in sprint 3. That's why the 0 values are shown in sprint 2 and the start of sprint 3.

| Sprint | Velocity planned | Real velocity |

|---|---|---|

| 1 | X | X |

| 2 | 0 | 0 |

| 3 | 0 | 1 week 2 hours |

| 4 | 2 weeks 30 minutes | 1 week 2 days 5 hours 30 minutes |

| 5 | 1 week 5 hours 30 minutes | 1 week 1 day 3 hours |

| 6 | 0 minutes | 1 week 3 days |

| 7 | 1 week 1 day 7 hours 30 minutes | 3 days 4 hours |

| 8 | 1 week 3 days | 1 week 3 days 3 hours |

| 9 | 1 week 3 hours | 4 days 1 hour 30 minutes |

| 10 | 2 weeks 4 days 6 hours 15 minutes | 3 days 3 hours 15 minutes |

| 11 | 7 hours | 2 weeks 3 days 3 hours |

| 12 | 5 hours | 1 week 6 hours 30 minutes |

| 13 | 2 weeks 2 days 1 hour 30 minutes | 7 hours |

For each sprint, a subset of items from the product backlog is selected and moved into the sprint backlog. This subset is determined during sprint planning, where the team collaboratively decides which items they can commit to completing within the sprint's time frame. The sprint backlog represents the specific set of work items that the team aims to accomplish during that sprint.

The backlog for each sprint provides focus and direction for the team, ensuring that they have a clear understanding of what needs to be done and can work towards achieving the sprint goals.

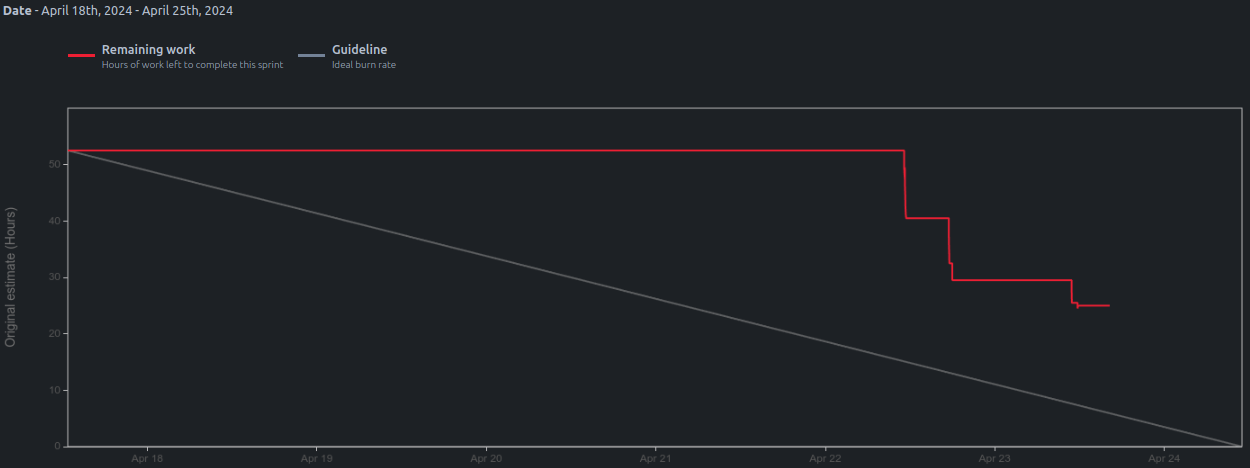

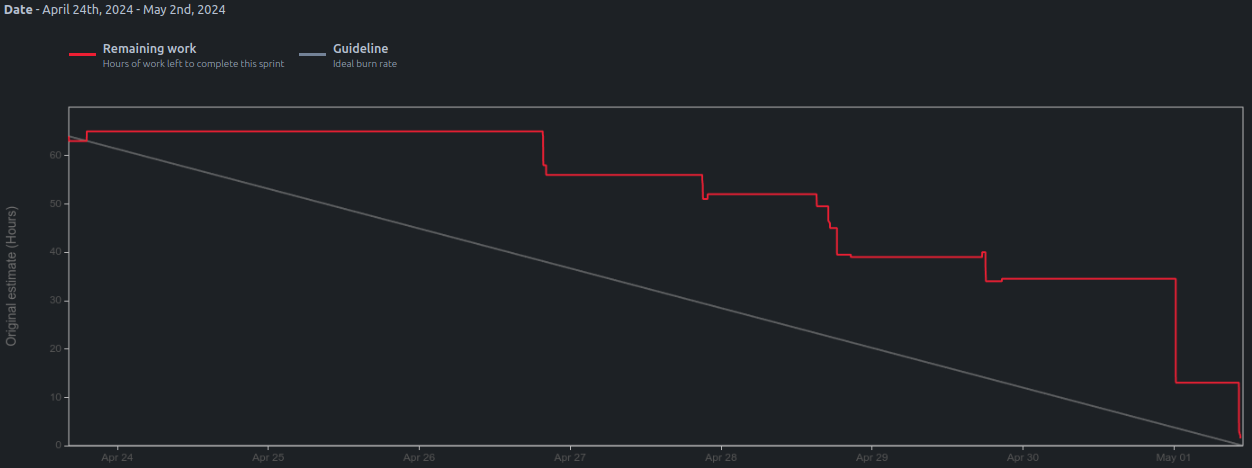

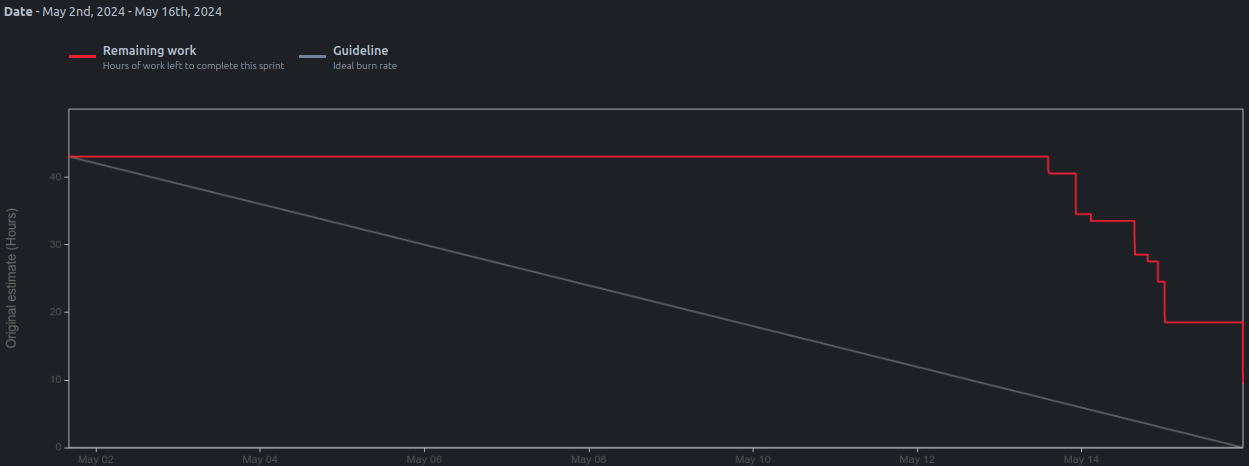

That is why for each sprint a link to the Jira filter that shows only that sprint’s task backlog is pasted, followed by the burndown chart.

A burndown chart is a graphical representation of the work completed versus the time remaining in a sprint. It typically shows the remaining effort (measured in time) on the vertical axis and the sprint duration on the horizontal axis.

At the beginning of the sprint, the burndown chart starts at the top, indicating the total amount of work remaining. As the team completes tasks throughout the sprint, the chart “burns down,” with the line trending downwards towards zero. The ideal scenario is for the chart to reach zero by the end of the sprint, indicating that all planned work has been completed.

The burndown chart provides valuable insights into the team's progress during the sprint. It helps stakeholders visualize whether the team is on track to complete the planned work or if they are falling behind schedule. If the burndown line deviates significantly from the ideal trend, it prompts the team to identify and address any issues or obstacles that may be impeding their progress. Additionally, it allows for course corrections to be made mid-sprint, ensuring that the team stays focused on achieving their sprint goals.

3.11.1 Sprint 1

No Jira data available for sprint 1

3.11.2 Sprint 2

3.11.3 Sprint 3

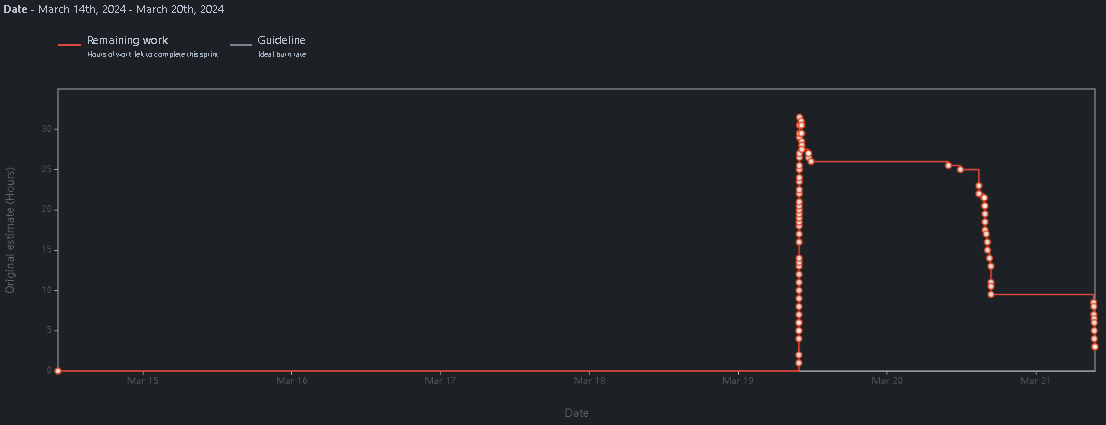

3.11.4 Sprint 4

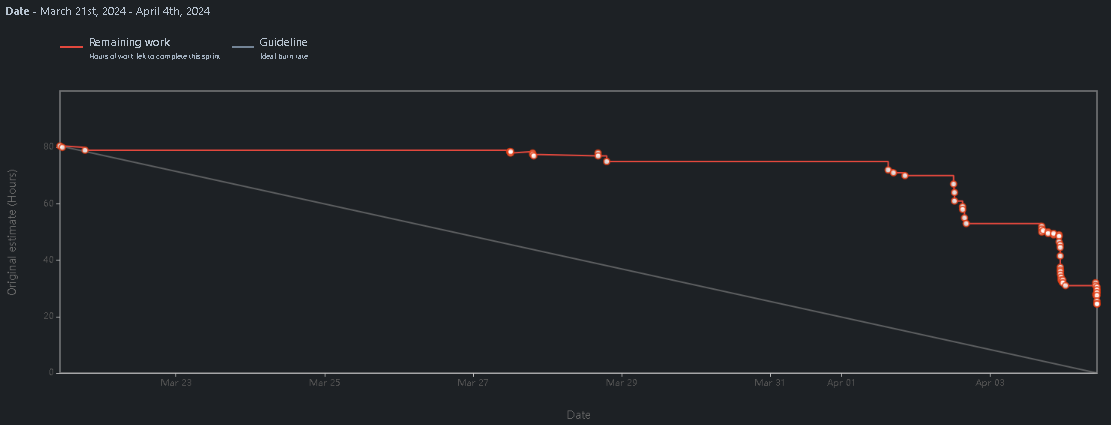

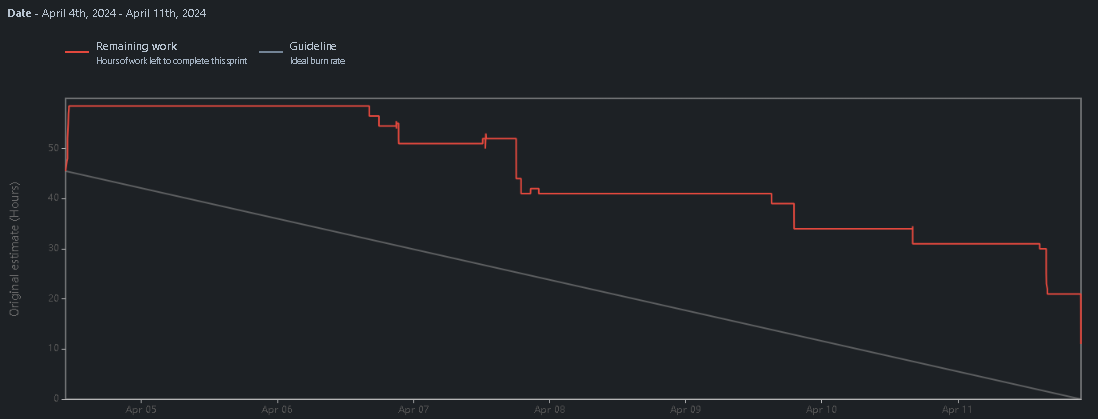

3.11.5 Sprint 5

3.11.6 Sprint 6

3.11.7 Sprint 7

3.11.8 Sprint 8

3.11.9 Sprint 9

3.11.10 Sprint 10

3.11.11 Sprint 11

3.11.12 Sprint 12

3.11.13 Sprint 13

3.12 Sprint Evaluations

For the retrospectives the team does the Good/Bad/Start/Stop and Actions retrospective with metroretro.io. For each Sprint only the link to the board and a table with the stickers information are included.

3.12.1 Sprint 1

No data available for this sprint

3.12.2 Sprint 2

Table 11 contains the 2nd Sprint Board stickers.

| Content | Zone |

|---|---|

| Finally a nice and convincing idea | Good |

| We Could find a good idea | Good |

| We did all the things we had to do | Good |

| We have a better plan and finished our sprint | Good |

| Planning is getting better | Good |

| It took us quite a long time to decide for an aidea | Bad |

| We dont inform each other enough what we have done | Bad |

| We defined the tasks at short notice | Bad |

| Not everyone is participating | Bad |

| Lack of work sometimes | Bad |

| Assign tasks the first day of the sprint | Start |

| We must start imputing time to jira tasks | Start |

| Make clear appointments | Start |

| We must comment all jira tasks in order to prove we did it and make it easy for other people to find our work | Start |

| We must be responsible with our jira tasks (make sure all our tasks finish on done state) | Start |

| Show up in time / let us know if you cannot be there | Start |

| Give tasks to hugo | Start |

| We have to stop being absent in meetings | Stop |

| Thinking about the old composter idea (i thnik everyone already did it) | Stop |

| quiting classes without telling | Stop |

| Not havong Done tasks commented or with imputed time at the end of the sprint | Actions |

| Anyone who disrispects any of the follo ing rules must bring cookies | Actions |

| Arriving late twice (+10 min) | Actions |

| No Excuses | Actions |

| Thursday morning is the most important day. Must be there | Actions |

| Not telling u wont come in the group | Actions |

3.12.3 Sprint 3

Table 12 contains the 3rd Sprint Board stickers.

| Content | Zone |

|---|---|

| Some people started using Jira propperly | Good |

| Finding the electronic parts and the schematics | Good |

| Most tasks completed | Good |

| The tasks are clear and organized | Good |

| Communication | Bad |

| We need to work more on our tasks | Bad |

| A few tasks were not on the done column | Bad |

| Some people do more work than others | Bad |

| We need to think about the final design, to be able to implement everything well | Start |

| Say if you are not there | Start |

| Communicate more the progress on our tasks | Start |

| We have to start using the time inputs and putting tasks in the column they have to be at each time | Start |

| Update people on what you are doing | Start |

| Check each others work | Start |

| We have to stop letting tasks for last minute, it can affect other people work | Stop |

| read each other work at the end of the tasks | Actions |

| Update the others on our tasks | Actions |

| Communicate if you are not there / late | Actions |

| Doing Standup dailies | Actions |

| Assign tasks equally on Jira | Actions |

3.12.4 Sprint 4

Table 13 contains the 4th Sprint Board stickers.

| Content | Zone |

|---|---|

| We commented the standup dailies | Good |

| We made a good progress during the vacation | Good |

| everybody is contributing and is working hard on their tasks | Good |

| unfinished tasks | Bad |

| not every task is done at the end of the spring | Bad |

| We planned this sprint with too much work and we couldn't finish all tasks | Bad |

| Nothing | Bad |

| Strat doing more stan-up dailies | Start |

| Communicate if you think you cannot finish your task, you can ask for help | Start |

| do more reviewing on the tasks from others | Start |

| Get an idea of how the final design should look like | Start |

| Growing mushrooms | Start |

| ignore messages in groupchat | Stop |

| Doing tasks without putting them to done in jira | Stop |

| stop editing in the wiki when somebody else is editing it at the same time | Stop |

| Taking Whatsapp messages more seriously | Actions |

3.12.5 Sprint 5

Table 14 contains the 5th Sprint Board stickers.

| Content | Zone |

|---|---|

| We delivered the report | Good |

| Everyone was prepared for the presentation | Good |

| I copied | Bad |

| We didn‘t control each tohers work | Bad |

| Lot of mistakes | Bad |

| Improving the report | Start |

| Sticking to agreements | Start |

| Completing the daily tasks | Start |

| Being late | Stop |

| Promising thhings you dont do | Stop |

| Taking Whatsapp messages more seriously | Actions |

3.12.6 Sprint 6

Table 15 contains the 6th Sprint Board stickers.

| Content | Zone |

|---|---|

| More people were on time | Good |

| We finished the 3d video | Good |

| Not all tasks were finished | Bad |

| Communication in the whatsapp group | Bad |

| Checking all weork | Start |

| Reviewing tasks | Start |

| Having a leader | Start |

| ignoring messages in whatsapp | Stop |

| letting unassigned tasks | Stop |

3.12.7 Sprint 7

Table 16 contains the 7th Sprint Board stickers.

| Content | Zone |

|---|---|

| Tasks were reviewed | Good |

| We almost finished the writings in the wiki | Good |

| To have a leader | Good |

| We started going to the lab | Good |

| Not comunicating the trouble in some tasks | Bad |

| unfinished tasks | Bad |

| I had unfinished tasks | Bad |

| finishing tasks! | Start |

| Being more accurate putting tasks | Start |

| Finishing the report | Start |

| stop editing the wiki without saying it in the whatsapp | Stop |

| Ignore whatsapp | Stop |

| doing tasks without marking them as done in jira | Stop |

| Not telling important information for the group | Stop |

| Meeting twice a week in stead of once | Actions |

| Brainstorm with the whole group for some topics | Actions |

| All tasks should be assigned | Actions |

| Finish tasks and communicate | Actions |

3.12.8 Sprint 8

Table 17 contains the 8th Sprint Board stickers.

| Improved interem report | Good |

| Solid report | Good |

| Almost all tasks were done | Good |

| we completed almost every task | Good |

| We delivered the report little bit in the limit | Bad |

| Not everything finished | Bad |

| We lost the 3D model | Bad |

| Working on the paper | Start |

| Start working on the paper | Start |

| Making backups for the report and other data | Start |

| Editing the wiki without announcing it | Stop |

| being late | Stop |

3.12.9 Sprint 9

Table 18 contains the 9th Sprint Board stickers.

| Improvedments on interem report | Good |

| Few tasks were not done | Good |

| We got back the 3D model | Good |

| We were late | Bad |

| imputing time on jira | Start |

| Editing the wiki without communicating | Stop |

3.12.10 Sprint 10

Table 19 contains the 10th Sprint Board stickers.

| The leader thing is working | Good |

| microcontroller from Paulo works really good, tested all the sensors and the actuators | Good |

| PRoces prototype and electronics | Good |

| microcontroller with cam does not work, in this case we will not been able to have a cam | Bad |

| Communication | Bad |

| There were some undone tasks | Bad |

| Finish tasks | Bad |

| WE did not do the monday meeting | Bad |

| functional test for 3D design | Start |

| Communicating | Start |

| Using jira properly | Start |

| Reading feedback in jira | Start |

| Doing more dailies | Start |

| working quick just to have the task done | Stop |

3.12.11 Sprint 11

Table 20 contains the 11th Sprint Board stickers.

| Functional tests | Good |

| We did the functional tests | Good |

| Unfinished tasks | Bad |

| Unifinished tasks | Bad |

| watering system | Bad |

| There were some tasks unfinished | Bad |

| finding solution for the water system | Start |

| doing teambuilding | Start |

| Finish your tasks and communicate | Start |

| Using jira | Start |

| not finishing your tasks | Stop |

3.12.12 Sprint 12

Table 21 contains the 12th Sprint Board stickers.

| teambuilding | Good |

| too large paper | Bad |

| We didn't have the paper ready on time | Bad |

| commenting tasks | Start |

| Doing tasks quickly just to put them to the done column | Stop |

3.12.13 Sprint 13

Table 22 contains the 13th Sprint Board stickers.

| Most tasks completed | Good |

| The tasks are clear and organized | Good |

| We need to work more on our tasks | Bad |

| Update people on what you are doing | Start |

| Check each others work | Start |

| Say if you are not there | Start |

| Letting tasks for last minute | Stop |

3.13 Conclusion

This chapter offers a detailed overview of the project team's approach for the semester ahead. It emphasizes the importance of a well-defined assignment, accompanied by a clear problem statement, ensuring that key stakeholders are considered and project milestones are achieved through effective planning. This solid groundwork allows the team to focus on other crucial aspects of the project.

In summary, project management emerges as a pivotal element in project execution, providing essential tools for organizing work effectively. Through meticulous objective setting, deadline management, and budget adherence, the team can prioritize tasks and enhance productivity. Furthermore, thorough risk, cost, quality, and communication analyses ensure comprehensive project management, enabling swift problem resolution and transparent stakeholder communication.

Moreover, the integration of daily and weekly monitoring, facilitated by the Scrum method and Jira platform, promotes reduced stress, heightened morale, and streamlined task management, thus optimizing project efficiency.

Moving forward, the subsequent chapter will explore marketing strategies and their critical role in project success, elucidating the adopted strategy and target audience considerations.

4. Marketing Plan

4.1 Introduction

In order to bring CoffeeMush to the market in the most attractive way possible, it is first necessary to be clear about the target market on which the product is to be focused. The intention is that the product will be used in kitchens, mainly for larger households / larger kitchens in e.g. hostels, hotels or even student residences, where space is not limited. Restaurants in urban areas are not really an option, because kitchens are often very small and space is more valuable for customers than for a kitchen composter. It would also be an option for hostels where users share the kitchen or for a flat with a common area where residents of all flats can dispose of their coffee waste and grow mushrooms.

To know the kind of market that needs to be researched, the target audience needs to be clarified. For this product the target audience is people who drink a lot of coffee. The most coffee is drunk in the North-West of Europe: Finland, Sweden, Norway, Denmark, Netherlands, Belgium. This will be the market of focus, but of course all coffee lovers can use the product. These countries consume almost 10 kg of coffee per person per year [Anonymous, 2024]. In this group of coffee drinkers, the target persona would be the people who are open to reusing their coffee waste for growing mushrooms.

Besides that, the aim is to make the product affordable and reach a large number of people so that they can start composting their coffee waste.

Next paragraph will analyse the market on a macro- and micro level.

4.2 Market Analysis

4.2.1 Micro Analysis

In the micro analysis the value proposition is defined. The value proposition is to motivate people to reuse their coffee waste to grow mushrooms. In this way the waste does not need to be processed and the mushrooms do not need to be produced and bought outside the house. This process saves money, environment and time. Compared to the kitchen composters that are on the market already, this composter produces mushrooms, where other composters produce a useless compost product.

4.2.2 Macro Analysis

In this macro analysis, the influences from other companies and cultural institutions that influence people’s behaviour, preferences, norms and values will be discussed. This is done by the PESTEL analysis, in which all letters represent a topic that can influence the target audience on deciding to (not) buy the product. The topics are political, economic, social, technological, environmental and legal. They are explained underneath.

Political

The rules and laws from the government on the smart kitchen composter influence the target audience. When changes are made by the government, it influences behaviour of the target audience. For example, in some countries people pay for the collection of their waste, which could motivate the target audience to reuse their coffee waste instead of throwing it away.

Economic

Economic reasons are a big motivator for people to decide on purchasing or not purchasing a product. This counts for the kitchen composter as well. The product is aimed to be cheap and thereby accessible for a large group of people.

And besides that, it accomplish the conditions to be considered as a circular economy system [Ellen Macarthur Foundatio, 2024].

Social

The social topics which influence the market of smart kitchen composters are population growth rates, age distribution, labour market trends and household sizes. The household sizes correlates for example to make it financially beneficial. If a household is just one, the coffee waste is less and the costs for waste collection are less than in a household of five coffee drinking people.

The social aspect of contributing to the environment is increasing. People are getting more aware of the environment and will talk about it with other people, convincing more and more people to take environmental friendly measures. This smart kitchen composter helps that as well. Besides that, nowadays mushrooms are perceived as healthy, tasty and their nutritional benefits can appeal to health-conscious consumers.

Technological

The smart kitchen composter is dependent on the technical progresses for sensors, apps and internet. An application will be made that adapts to the composter and shows the progress of the composting process. In the future, this application will have to be updated to the standards of the time. And of course the mushroom process itself can be improved from investigations in order to minimize the time or improve the efficiency.

Environmental

The smart kitchen composter is sustainable, as it reuses the coffee waste for growing the mushrooms. This may people is motivated to purchase the kitchen composter, most people in the North-West of Europe are well aware of the environmental problems and want to contribute to help the environment. And compared to other composting methods growing mushrooms on recycled waste has a lower carbon footprint compared to traditional farming methods [Nick Robinson, 2024].

Legal

For the app, there are laws about privacy and security that need to be followed. Besides there are safety rules that need to be followed about electrical devices, like this composter with sensors. These rules and laws need to be researched and followed.

SWOT analysis will be done in the following paragraph, enlightening the strengths, weaknesses, oppertunities and threats of CoffeeMush on the market.

4.3 SWOT Analysis

SWOT refers to strengths, weaknesses, opportunities and threats on the market. It is crucial to consider these aspects for the kitchen composter. This will help to understand the constraints to watch out for and the opportunities to explore.

Strengths

- Reuse waste

- Save money

- Innovative

- Environmental friendly

- Local source of food

- Reaching people of lower financial classes

Weaknesses

- Quite some space needed

- Only coffee can be composted

- Mushrooms can also be grown in coffee ground without a smart device

Opportunities

- Market with potential

- People want to contribute to the environment

Threats

- Competitors

- Price sensitivity of consumers

The marketing strategy of CoffeeMush will be discussed in detail in the next paragraph.

4.4 Strategy

4.4.1 Strategic Objectives

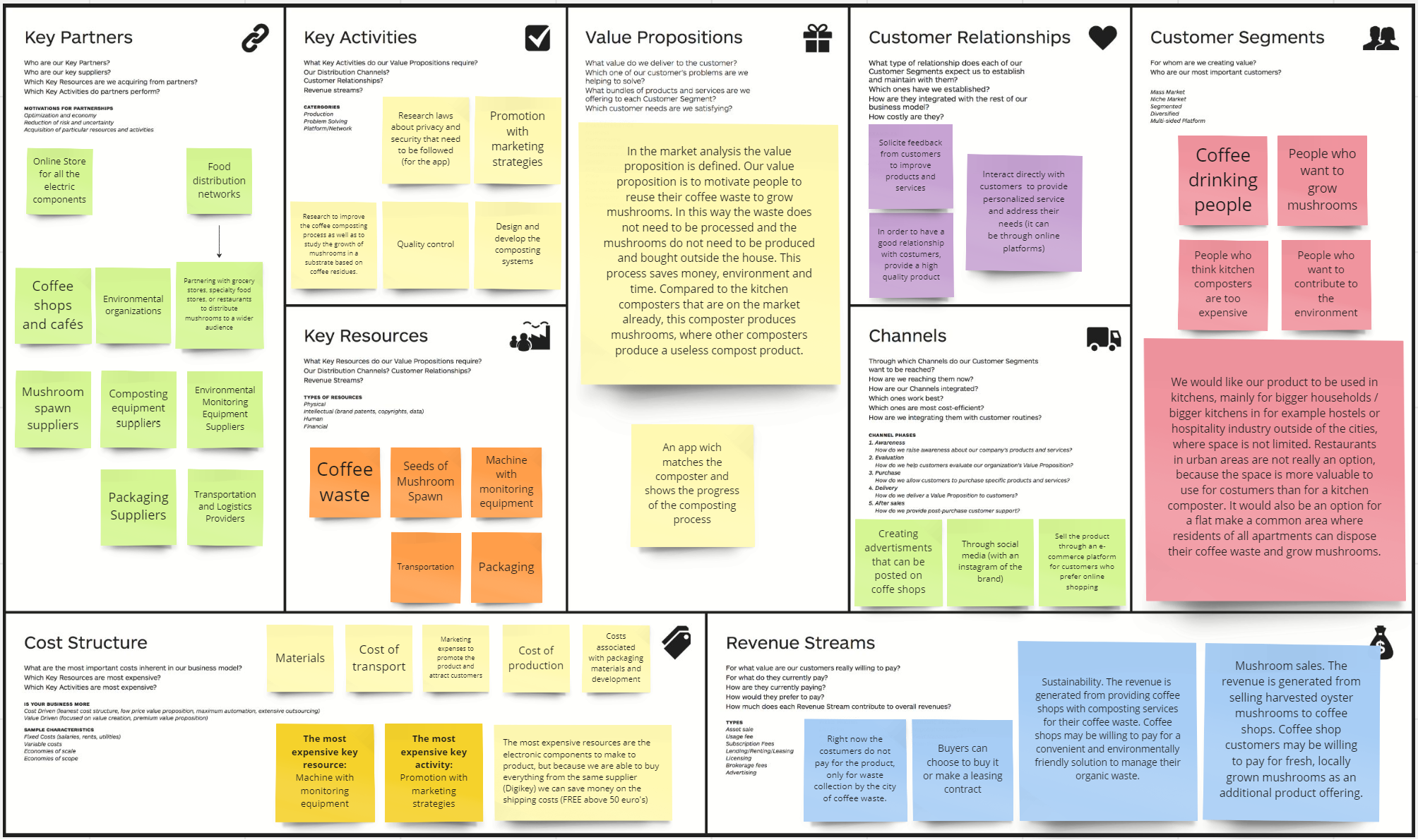

In order to get a good market position, it is important to determine what to aim for in the market. For this, the Business Model Canvas is made an shown in Figure 28.

4.4.2 Segmentation and Targeting

Segmentation:

In marketing segmentation the customers on the market are divided into different parts to get a clearer understanding of the customers that the products focusses on. The segmentation can be done judging on demographical, geographical, behavioural or psychological aspects. For CoffeeMush, geographical distribution holds minimal significance as the product functions effectively based on the combined demand from both northern and other regions, ensuring sustained operations. More eminent is the behaviour and demographical aspects. The customer segment that is focussed on should show a stable life, meaning that the income is steady and the household is arranged. Furthermore, the behaviour should show interest in coffee waste, mushrooms and/or composting.

Target audience:

CoffeeMush be used in kitchens, mainly for bigger households / bigger kitchens in for example hostels or hospitality industry outside of the cities, where space is not limited. It would also be an option for a flat make a common area where residents of all apartments can dispose their coffee waste and grow mushrooms. Thirdly the product could be used in big households, where there is enough space for the product. The age and income of the target audience is in a wide range. Approximately between 20 and 80 years old and an average to high income.

The product is attractive for people who drink a lot of coffee, eat a lot of mushrooms, or want to contribute to the environment by processing coffee waste sustainably.

4.4.3 Positioning

CoffeeMush is a product that is different to any other product on the market. There are a lot of kitchen composters on the market, but they do not make a product that is useful for further fertilization or growth. In this way CoffeeMush distinguishes itself; the product mushrooms can actually be eaten. In addition, it is intended to stand out by making the product more accessible and less expensive. The only products that do something similar to CoffeeMush are way too expensive as pointed out in figure 29

Exploring a potential avenue, our company is contemplating the introduction of a secondary business model centered around the distribution of mushroom spawns via a monthly subscription arrangement.

4.4.4 Marketing-Mix

In the marketing mix, the four P’s—product, price, place, and promotion—play vital roles in shaping CoffeeMush's market strategy and consumer engagement.